Laser Marking Wood With a CO2 System

Industry: Consumer Goods

Material: Wood

Mark Data Type: Graphics, logo

Laser Mark Type: Engraved,...

Types of laser marking generally fall into one of three categories: Ablation, Engraving and Stain marking.

Ablation marking involves removing a film or layer of material on the part. The stark white marking achieved on anodized aluminum is an example of ablation marking. The anodize is ablated away and a white oxide layer is formed on the surface of the part resulting in a white mark. Ablation marking is not particularly sensitive to laser spot size.

Ablation marking involves removing a film or layer of material on the part. The stark white marking achieved on anodized aluminum is an example of ablation marking. The anodize is ablated away and a white oxide layer is formed on the surface of the part resulting in a white mark. Ablation marking is not particularly sensitive to laser spot size.

Engraving is just as the name implies. The focused laser beam will vaporize material from the surface of the part resulting in marking depths as deep as .1 inches. Deep engraving almost always requires multiple laser passes and each pass removes a thin layer of material. Generally speaking, smaller spot sizes yield better results when an engraving technique is used. (Click image to enlarge.)

Stain marking is one of the most useful marking techniques for fiber lasers, but it is also one of the most misunderstood techniques.

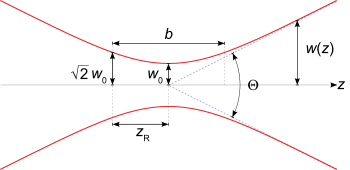

Stain marking can provide a permanent, dark mark on stainless steel, titanium and hard chrome. The stain mark is accomplished by using a relatively large focused spot size in order to heat the surface of the part sufficiently such that an oxide layer is formed on its surface but the laser beam will not vaporize material from the surface. The technique most commonly used to increase the size of the focused laser spot size is to simply move the lens away from the work piece so that it is no longer in focus.

This is a poor technique for the following reasons:

1. Marking at a distance other than the focal point of the lens can be subjective and hard to repeat.

2. When the lens on a steered beam marker is moved away from the focal point, the field size calibration is no longer correct and marking will not be to size.

3. When marking on a curved surface, the focused spot size will change as the laser beam is moved over the curvature of the part.

How far one can mark around that curvature is mainly determined by the “depth of focus” of the optical system. If the lens is already been placed out of focus in order to achieve the correct spot size for a stain mark then there is no depth of focus available. Marking around a curved surface with an out of focus laser beam makes stain marking difficult, if not impossible. (For more information on focused laser beams check out this article if you are interested). The diagram below illustrates how the laser beam acts at the focal point and on either side of the focal point. There is no depth of focus with an out of focus lens.

Please contact Jimani if we can help you with you laser marking.

Industry: Consumer Goods

Material: Wood

Mark Data Type: Graphics, logo

Laser Mark Type: Engraved,...

When creating a permanent traceability mark, identifying mark, or decorative mark on wood products...

A young girl came to Jimani and wanted her grandfather’s favorite recipe engraved on a piece of...