Laser Engraving Services

Our Job Shop

- Home

- Laser Job Shop

Laser Marking and Engraving Services

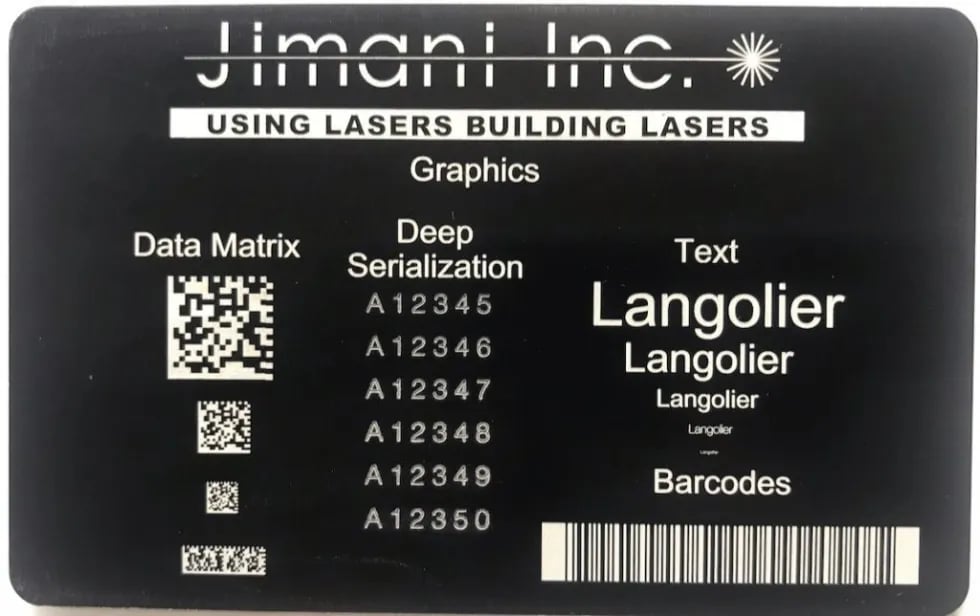

Jimani has performed laser marking and engraving job shop services since 1990. We have consistently provided timely, high quality marking on a wide variety of product using both Fiber and CO2 steered beam laser marking systems.

Every customer and job is unique. Jimani strives to offer the most competitive pricing and is willing to work within your budget.

Pricing can vary greatly depending on the size of the mark, the material used, product packaging, and the type of engraving selected. That is why flat rate pricing is hard to quote without all that information.

We want to show you how our pricing is formulated so you can understand what your job will cost before we quote you.*

- Logo / Artwork Charge: $60.50

- Machine Set up charge: $33.50

- Text, Logo, Text w/logo, Variable data

- Serial numbers and barcodes are quoted on an individual basis

- Personalization - Price depends on size, material and laser run time per item.

Our average turnaround time is 3-5 days, depending on the quantity.

However, we offer same-day and next-day rush service on some orders for an additional price. We accept single custom items, large quantity orders, and everything in between.

Please view our gallery to see examples of the material and mark type capabilities.

* Large quantity industrial customers require special pricing, so please contact us for a quote today!

Fiber Laser Marking and Engraving

All metals are good candidates for being marked and engraved with a fiber laser. The terms marking and engraving are frequently used interchangeably but there is a difference. Marking depths are generally just microns deep into the surface whereas engraving depths are in mils (thousandths of an inch) into the surface. Although it is possible to mark as deep into a metal surface as is desired, going beyond .015-.020” is usually not very practical and very deep engraving applications are usually better served with more traditional engraving tools such as rotary mechanical engravers.

Marking field sizes (size of the marking field, not the part) range from about 5 inches square to about 12 inches square. Smaller marking fields are better for deeper engraving because the laser beam focuses to a smaller spot with smaller marking field lenses. If the required marking area exceeds the marking field of the lens then the part must be repositioned to accommodate the size of the marking.

Marking on cylindrical surfaces can be done and the distance that the mark can be “wrapped” around the part depends on the diameter of the part and the depth of focus of the lens. As a general rule, one could mark about 60 degrees around the circumference of a 1 inch diameter part without rotating the part or distorting the mark. Beyond that distance, the part must be rotated. Rotary and linear “tiling” allows full 360 degree marking on cylindrical surfaces and marking over the entire length of the linear stage travel.

-

Laser marking on anodized aluminum

-

Laser engraving into steel

-

Laser marking on plastic

-

Black Stain marking on stainless steel

The actual marking can be in the form of human readable text, machine readable text (1D and 2D barcodes), serial numbers. Because a fiber laser can focus to a very small spot, very high marking resolution can be obtained.

As stated earlier, all metals, coated, plated or bare, are good candidates for fiber laser marking and engraving. Some, but not all, plastic materials mark well with a fiber laser. Marking rather than engraving is almost always the goal with plastics. Ideally, dark colored plastics can achieve light colored marking and light colored plastics can achieve dark colored marking.

More information about fiber laser marking can be found in the links below or on the Jimani laser marking blog.

https://www.jimani-inc.com/blog/laser-marking-vs-engraving

https://www.jimani-inc.com/blog/laser-marking-201-marking-various-types-of-products

CO2 Laser Marking and Engraving

CO2 lasers have a different wavelength (color of the laser light) than fiber lasers and because of this the light from a CO2 laser works with different materials than does a fiber laser. While a fiber laser is great for marking on all metals, a CO2 laser is exactly the wrong choice for metal marking. Wood, glass, plastics, non-metals and organic materials are best marked with a CO2 laser.

The longer wavelength of a CO2 laser also means that it will not have the same fine linewidth as a fiber laser. This means that a CO2 laser cannot achieve the same detailed marking resolution as a fiber laser.