Laser Etching Glass: Achieving Superior Results with No Flaking or Chipping

Laser etching glass produces a frosted direct part mark on a traditionally difficult-to-mark...

By: Jim Earman on 6/24/25 8:00 AM

In the early 1970s, the idea of coupling a laser beam to a pair of computer-controlled galvanometers began to take root. By bouncing a laser beam off of reflective mirrors attached to scanning galvanometers, the laser beam could then be focused onto a part.

As the galvanometers “steered” the laser beam across the part, patterns could be drawn on the part with the focused laser beam. I was working for Korad Lasers at the time and had an opportunity to witness and participate in the development of galvo-driven laser marking systems.

The First Fiber Laser Marking Systems

The First Fiber Laser Marking SystemsThe first commercially available steered beam laser marking systems were designed and built by 3 different entities:

Those first systems were crude by today’s standards. Personal computers and their associated software programs just didn’t exist in 1973 and 1074. Almost all early steered beam (galvo driven) laser marking consisted of marking simple alphanumeric characters. Those marked characters, for the most part, consisted of single-line “stick fonts”.

True Type fonts that are now universally used had not been developed. Although the laser beam/scanning galvanometer combination was not just limited to marking crude alpha numeric characters, there was not a lot of interest in decorative marking such as marking individual corporate logos on items.

Most galvo-driven laser marking systems are used for metal marking applications and for decades Nd:YAG lasers were used because the 1064 nm wavelength of a YAG laser is ideal for all metals. YAG lasers were expensive to build and required a lot of maintenance. YAG lasers were also limited in output power. The best YAG lasers could only produce 20 or so watts of high-quality 1064 nm light.

The price of YAG marking systems was around $50K on the low end and hundreds of thousands of dollars on the high end. This high price coupled with the maintenance and power requirements of those systems limited their use to larger companies with larger budgets. All of that began to change in the early 2000s with the introduction of fiber lasers and China’s entry into the galvo driver laser marking industry.

Fiber laser technology was developed by a Russian company named IPG. Fiber lasers could produce the same output wavelength as YAG lasers. My first impression of fiber lasers was that the technology was too good to be true. Fiber lasers had the advantages of much smaller size, extremely high wall plug efficiency as compared to YAGs, long component life with no consumables and essentially no maintenance.

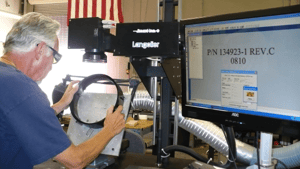

After only a few years after the introduction of fiber laser technology, those lasers could produce as much high-quality 1064 nm laser output as the most powerful YAG lasers. Fiber lasers were now a suitable replacement for YAG lasers in galvo-driven marking systems. A few companies, Jimani included, designed marking systems around fiber laser technology. The trade name for Jimani’s Fiber Laser Marking System was The Langolier.

After only a few years after the introduction of fiber laser technology, those lasers could produce as much high-quality 1064 nm laser output as the most powerful YAG lasers. Fiber lasers were now a suitable replacement for YAG lasers in galvo-driven marking systems. A few companies, Jimani included, designed marking systems around fiber laser technology. The trade name for Jimani’s Fiber Laser Marking System was The Langolier.

Although fiber lasers were much cheaper to build and maintain, the price of fiber laser modules and fiber laser marking systems remained pretty much unchanged. My take on this is that prices were based on cost per watt of laser output rather than manufacturing costs. Prices for fiber laser marking systems took a dramatic change when Chinese integrators began selling laser marking systems in about 2007.

The first Chinese-made galvo-driven laser marking systems were introduced in about 2007. Those systems used both Chinese made fiber laser sources (primarily JPT or Raycus laser sources) or US-made fiber laser sources (primarily IPG or Nufern laser sources). Scanheads (which contain the scanning galvanometers) were either US or German-made devices, but Chinese companies soon developed their scanhead technology.

Expensive US and German laser marking software packages were replaced with Chinese-made EZ Cad laser marking software and JCZ control electronics. EZ Cad and JCZ control boards were a fraction of the price of traditional software and control electronics packages. The price of the Chinese marking systems was ½ or less of the price of US marking systems.

It became clear that US marking system integrators were paying considerably more for identical components than Chinese integrators were paying. In addition to that, Chinese-made fiber laser sources and scanhead technology have become quite reliable at a much lower price. Nufern got out of the fiber laser business, IPG announced some dramatic price reductions on laser sources, and scanhead manufacturers began introducing low-cost scanheads to compete with Chinese-made scanheads and optics. The price war had begun.

Over the years, prices for galvo-driven laser marking systems has gotten lower, particularly the Chinese-made systems or US-made systems with major components from China. Prices for Chinese markers have become a race to the bottom. Cheaper lasers, scanheads, optics and related making hardware have all contributed to pricing policies. Prices for some systems are now so low that many users just replace failed marking systems rather than repairing them.

My experience has been that a reduction in the price of a laser marking system always means a reduction in the quality of components in that system. If the price is low enough, replacing rather than repairing it makes sense. Support in these very low-priced systems is pretty much non-existent anyway. If the seller made little or no money on the sale, then how much time, effort, and money can that company spend on support? In many instances, the answer is “little or none”.

Low-cost fiber laser technology has allowed small companies and individuals to jump into the laser marking business. As the sales of fiber laser marking systems have increased, so have the number of integrators and resellers of those systems. Some of these integrators simply import and rebrand marking systems and then resell them under their own name. Other integrators import lower-cost major components and integrate them into their own marking system design.

Low-cost fiber laser technology has allowed small companies and individuals to jump into the laser marking business. As the sales of fiber laser marking systems have increased, so have the number of integrators and resellers of those systems. Some of these integrators simply import and rebrand marking systems and then resell them under their own name. Other integrators import lower-cost major components and integrate them into their own marking system design.

In about 2010, Jimani was approached by a Chinese marker manufacturer. They wanted to know if we would be interested in selling and supporting their markers in the US. I asked why they had contacted us given the large price difference between Jimani-made systems and Chinese-made systems.

Their answer was “support”. Jimani has a good reputation for supporting our marking systems, and the Chinese struggled supporting their own systems sold in the US. They sent a system to Jimani for testing. That system was equipped with a 20-watt US-made Nufern laser, a Chinese-made Galvotech scanhead, and EZ Cad software. The laser and scanhead worked as well as expected, but the EZ Cad software was buggy and clumsy to use.

When I asked the Chinese company that had approached us about software bugs, they gave me an answer that has stuck with me. They told me that in the US, if a software package has bugs, then their US customers expect those bugs to be fixed. In China, if a software package has bugs, the operator just learns not to use the functions that don’t work well. That told me a lot about the Chinese business philosophy. Jimani returned that first system. A year or so later, we were again contacted by the same individual who sold us the first system. He had started his own laser marker integration company and wanted to partner with Jimani in order to gain a foothold in the US market.

Jimani’s Langolier was an excellent system but was very expensive compared to almost all of the markers coming from China. Rather than just importing and rebranding products Jimani took the approach of bringing in some of the major lower-priced, labor-intensive components and integrating them into a system that uses the same software, control electronics, and optical configuration as the Langolier.

We called that system the Low-Cost Hybrid Laser Marking System. Although the Low-Cost Hybrid is still more expensive than complete marking systems imported from China, it is 1/3 the price of a Langolier and has the same marking performance as the Langolier. More importantly, it is supportable.

Laser etching glass produces a frosted direct part mark on a traditionally difficult-to-mark...

Not all laser marking applications require a fully featured, top-of-the-line laser system. In fact,...

When I recently placed an order for a few new IPG YLP type lasers to be used in Jimani Langolier...