Hybrid Fiber Laser System Support

What Industrial Buyers Need to Know

When your production line depends on consistent laser marking, support quality becomes as critical as the equipment itself. A fiber laser system that delivers precision marks at high speed means nothing if you can't get help when you need it or if the system fails during a critical production run.

Industrial buyers face a challenging reality: most laser marking vendors excel at selling systems but struggle with long-term support. The result is costly downtime, delayed shipments, and frustrated production teams. Understanding what separates reliable support from empty promises can save your operation thousands in lost productivity.

Reliability: Built for Your Production Reality

Industrial-grade reliability starts with component selection and system design. Quality fiber laser systems use proven galvanometer scanheads, not cost-reduced alternatives that fail under continuous operation.

At Jimani, our hybrid systems integrate JPT MOPA fiber lasers with Galvo Tech scanheads and RTC control boards. These components have established track records in demanding manufacturing environments. More importantly, we maintain complete documentation on every component, including failure modes and replacement procedures.

The difference shows in real-world performance. Our industrial customers report average uptimes exceeding 98% over multi-year periods. This reliability comes from selecting components that handle thermal cycling, vibration, and contamination without degrading marking quality.

Speed Without Compromise

Marking speed matters, but not at the expense of read rates or mark quality. Many suppliers quote impressive speeds that only apply to simple text under ideal conditions. Real production marking involves complex geometries, varying materials, and quality requirements that demand consistent performance.

Our hybrid systems maintain marking accuracy across the full speed range. A typical part number with 2D DataMatrix code marks in under 2 seconds on anodized aluminum, with first-pass read rates above 98%. The galvo control system compensates for acceleration and deceleration automatically, ensuring uniform mark quality regardless of complexity.

Speed also depends on setup efficiency. Our workstations provide 19 inches of Z-axis travel with repeatable positioning. Operators can switch between part types without lengthy recalibration, maintaining throughput during product changeovers.

Software That Works for Production

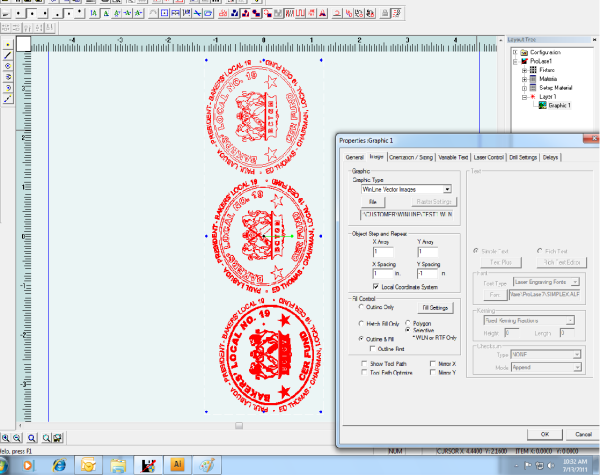

Production environments need software that handles complexity without creating operator errors. The included Leopardmark software manages serialization, database connectivity, and quality logging through intuitive interfaces. Operators can set up new jobs without programming knowledge, while maintaining full control over marking parameters.

For applications requiring advanced features, Prolase software upgrade provides rotary axis control, rotary tiling, and custom automation interfaces. The software communicates directly with PLCs and manufacturing execution systems, integrating seamlessly into existing production workflows.

Both software packages include unlimited operational support. When your team encounters an unfamiliar marking requirement or integration challenge, our support engineers provide direct assistance without service fees or support ticket delays.

Support When You Need It

Support quality varies dramatically across laser marking suppliers. Many vendors provide limited phone support during business hours, leaving production teams stranded during evening or weekend shifts. Others outsource support to third parties who lack deep product knowledge.

Jimani provides direct support from the engineers who build and use these systems daily. Our job shop operation means we encounter the same marking challenges our customers face. When you call with a production issue, you reach people who have solved similar problems firsthand.

Support includes more than troubleshooting. We maintain complete application databases with marking parameters for thousands of material combinations. Need to mark a new plastic grade or metal alloy? We provide tested parameters that work, not theoretical starting points that waste production time.

Integration for Modern Manufacturing

Modern production requires laser markers that communicate with existing systems. Our hybrid systems include Ethernet connectivity and standard industrial protocols. Integration with barcode scanners, database systems, and production tracking happens through documented interfaces, not custom programming.

The marking software exports production data in standard formats compatible with quality management systems. Traceability requirements for medical devices, aerospace components, or automotive parts integrate directly into existing documentation workflows.

For automated applications, the system accepts part present signals and provides marking complete outputs. Integration with robotics or conveyor systems follows standard industrial practices, reducing installation complexity and long-term maintenance requirements.

Flexibility Across Materials and Applications

Production flexibility requires handling multiple materials without extensive setup changes. Our reversible beam expander allows optimization for both fine detail marking and broader coverage applications. The same system marks intricate medical device identifiers and large aerospace part numbers with equal precision.

Material compatibility extends beyond metals. The 1064nm wavelength handles engineered plastics, ceramics, and composite materials common in modern manufacturing. Marking parameters adapt automatically based on material selection, maintaining consistent results across diverse applications.

The modular design accommodates future requirements. Additional rotary axes, extended marking fields, or specialized fixturing integrate without replacing core system components. Your investment adapts as production requirements evolve.

Making the Right Choice

Evaluating fiber laser system support requires looking beyond initial equipment cost. Consider the total cost of ownership, including training time, spare parts availability, and support responsiveness. Systems that cost less upfront often create higher long-term expenses through downtime and integration difficulties.

Jimani's hybrid systems provide proven performance with comprehensive support. Our customers return for additional systems because the support quality matches the equipment reliability. When your production depends on consistent marking performance, that combination delivers measurable value.

Ready to evaluate how hybrid fiber laser systems can improve your marking operations? Contact our team to discuss your specific requirements.